Mountain Sky Limited established in 1997 in Hong Kong. With continuous development, the company expanded the manufacturing facilities to Zhuhai China and setup the subsidiary called "Zhu Hai Jin Tai Shan Plastic Products Co., Ltd”.

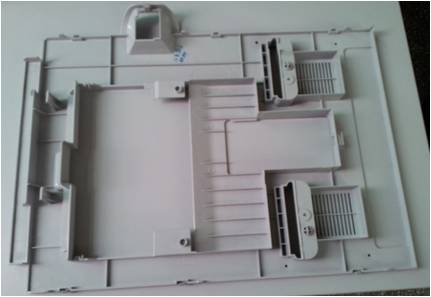

Jin Thai Shan is specialized in tooling, plastic injection molding, silk screen and pad stamping, as well as assembling of plastic products. The factory occupied 9000 square meter of manufacturing area, and over 200 staff during the peak season.

The facility is well equipped with tooling workshop, injection workshop, printing and assembling workshop, which is capable for “one stop service from tooling design to mass production of finished product.

Mountain Sky is experienced in wide range of products including consumer appliances, electronic components, medical, hardware goods, household and accessories etc.

Our service is including:

• CAD design/mold flow analysis/DFM

• Custom and tailor made injection tooling

• Plastic injection molding

• Silk Screen, and pad printing

• Assembly

1

To enhance and develop business oppurtunity to diversify products that meets the competitive market for both overseas and China

2

• Manufacturing and supplying quality products and provide a total solution that satisfy the needs of our customers

• Advancement in the manufacturing and management to acheive operational excellence

3

We are committed to provide our customers by focusing on the following:

•To meet customer requirements and development

•To keep quality of manufacturings at 98%

•By competitve offers to achieve Win Win

•To provide on-time delivery and service

We were accredited by ISO 9001:2008 which further heightens customer confidence. The world-class quality standard ensures that very single piece of product produced passes quality control in every process of production line to the delivery.

• More than 10 years injection tooling design experience.

• Custom & tailor-made injection tooling per clients' request.

• Competitive prices

• own mold designers and mold making facilities.

• With moldflow simulation and 2d/3d software.

We always doing our best to turn our customers' great idea into a reality.

• Experienced engineers, designers and technicians.

• Strong experience with tooling and engineering.

• In-house tooling making facility.

• Quick prototype.

• 21 plastic injection molding machines

• up to 650-ton capacity

• Two-tone injection molding machines

•Over 1500 sq meters assembly floor space.

•2 assembling line in painting and silkscreen department.

•Dust-proof environment works

Hong Kong Address: FLT D, 27/F BLK6, Maywood Court Kingswood Villas, Tin Shui Wai NT.Tel: 28841135

Factory:No.192 Qinshi Road,Sanzao Town, Jinwan District, Zhuhai City, Guangdong Province, ChinaTel: 0756-7516560;Email:info@mountainsky.com.hk